Different Types of Chassis (Cont'l)

Glass-Fiber body

To

many sports cars specialists, glass-fiber is a perfect material. It

is lighter than steel and aluminium, easy to be shaped and rust-proof.

Moreover, the most important is that it is cheap to be produced in

small

quantity - it needs only simple tooling and a pair of hands. There are

a few drawbacks, though: 1) Higher tolerence in dimensions leads to

bigger

assembly gaps can be seen. This is usually percieved as lower visual

quality

compare with steel monocoque. 2) Image problem. Many people don't like

"plastic cars".

To

many sports cars specialists, glass-fiber is a perfect material. It

is lighter than steel and aluminium, easy to be shaped and rust-proof.

Moreover, the most important is that it is cheap to be produced in

small

quantity - it needs only simple tooling and a pair of hands. There are

a few drawbacks, though: 1) Higher tolerence in dimensions leads to

bigger

assembly gaps can be seen. This is usually percieved as lower visual

quality

compare with steel monocoque. 2) Image problem. Many people don't like

"plastic cars".

Glass-fiber has

become a

must for British sports car specialists because it is the only way to

make

small quantity of cars economically. In 1957, Lotus pioneered

Glass-Fiber

Monocoque chassis in Elite (see picture). The whole mechanical stressed

structure was made of glass-fiber, which had the advantage of

lightweight

and rigidity like today's carbon-fiber monocoque. Engine, transmission

and suspensions were bolted onto the glass-fiber body. As a result, the

whole car weighed as light as 660 kg.

However, this radical

attempt

caused too many problems to Colin Chapman. Since the connecting points

between the glass-fiber body and suspensions / engine required very

small

tolerances, which was difficult for glass-fiber, Lotus actually

scrapped

many out-of-specification body. Others had to be corrected with

intensive

care. As a result, every Elite was built in loss. Since then, no any

other

car tried this idea again.

Today, no matter

Lotus, TVR,

Marcos, GM's Corvette / Camaro / Firebird, Venturi and more, employ

glass-fiber

in non-stressed upper body. In other words, they just act as a

beautiful

enclosure and provide aerodynamic efficiency. The stressed chassises

are

usually backbone, tubular space-frame, aluminium space-frame or even

monocoque.

| Advantage: |

Lightweight.

Cheap to be produced in small quantity. Rust-proof. |

| Disadvantage: |

Lower visual

quality. Unable

to act as stressed member. |

| Who use it ? |

Lotus, TVR,

Marcos, Corvette,

Camaro, Firebird ... |

Carbon-Fiber Monocoque

Carbon Fiber is the most

sophisticated

material using in aircrafts, spaceships and racing cars because of its

superior rigidity-to-weight ratio. In the early 80s, FIA established

Group

B racing category, which allowed the use of virtually any technology

available

as long as a minimum of 200 road cars are made. As a result, road cars

featuring Carbon-Fiber body panels started to appear, such as Ferrari

288GTO

and Porsche 959.

There are several

Carbon-fibers

commonly used in motor industry. Kevlar, which was developed by Du

Pont,

offers the highest rigidity-to-weight ratio among them. Because of

this,

US army's helmets are made of Kevlar. Kevlar can also be found in the

body

panels of many exotic cars, although most of them simultaneously use

other

kinds of carbon-fiber in even larger amount.

Production process

Carbon-fiber panels are

made

by growing carbon-fiber sheets (something look like textile) in either

side of an aluminium foil. The foil, which defines the shape of the

panel,

is sticked with several layers of carbon fiber sheets impregnated with

resin, then cooked in a big oven for 3 hours at 120°C and 90 psi

pressure.

After that, the carbon fiber layers will be melted and form a

uniformal,

rigid body panel.

Carbon-Fiber Panels VS Carbon-Fiber Monocoque

Chassis

|

Porsche 959,

employed carbon-fiber

in body panels only, is obviously .... |

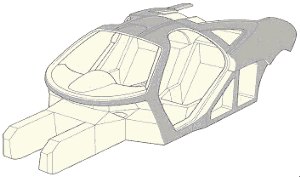

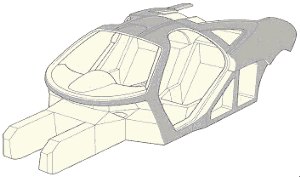

|

.... inferior

to McLaren

F1's carbon-fiber monocoque. This structure not only supports the

engine

/ drivetrain and suspensions, it also serves as a very rigid survival

cell. |

Exotic car makers like

to tell

you their cars employ carbon-fiber in construction. This sounds very

advanced,

but you must ask one more question - where is the carbon-fiber used ?

Body

panels or Chassis ?

Most so-called

"supercars"

use carbon-fiber in body panels only, such as Porsche 959, Ferrari

288GTO,

Ferrari F40 and even lately, the Porsche 911 GT1. Since body panels do

nothing to provide mechanical strength, the use of carbon fiber over

aluminium

can barely save weight. The stress member remains to be the chassis,

which

is usually in heavier and weaker steel tubular frame.

What really

sophisticated

is carbon-fiber monocoque chassis, which had only ever appeared in

McLaren

F1, Bugatti EB110SS (not EB110GT) and Ferrari F50. It provides superior

rigidity yet optimise weight. No other chassis could be better.

Carbon Fiber

Monocoque made

its debut in 1981 with McLaren's MP4/1 Formula One racing car, designed

by John Barnard. No wonder McLaren F1 is the first road car to feature

it.

| Car |

Body

|

Chassis |

| Ferrari 288GTO

(1985) |

carbon fiber

panels |

steel tubular

space frame |

| Porsche 959

(1987) |

carbon fiber

panels |

steel monocoque |

| Ferrari F40

(1988) |

carbon fiber

panels + doors |

steel tubular

space frame |

| McLaren F1 (1993) |

carbon fiber

panels |

carbon fiber

monocoque |

| Ferrari F50

(1996) |

carbon fiber

panels + doors |

carbon fiber

monocoque |

| Lamborghini

Diablo SV (1998) |

mostly

aluminium

panels, with carbon fiber bonnet + engine lid |

steel

tubular

space frame |

| Lamborghini

Diablo GT (1999) |

mostly carbon

fiber panels

+ aluminium doors |

steel tubular

space frame |

Engine act as stressed member - Ferrari F50

|

Unlike McLaren

F1, Ferrari

F50's rear suspensions are directly bonded to the engine / gearbox

assembly.

This means the engine becomes the stressed member which supports the

load

from rear axle. Then, the whole engine / gearbox / rear suspensions

structure

is bonded into the carbon fiber chassis through light alloy. This is a

first for a road car.

Advantage:

lighter still.

Disadvantage:

engine's vibration

directly transfers to the body and cockpit.

|

In 1963, a revolutionary

chassis

structure appeared in Formula One, that is, the championship-winning

Lotus

25. Once again, that was innovated by Colin Chapman. Chapman used the

engine

/ gearbox as mounting points for rear suspensions in order to reduce

the

width of his car as well as to reduce weight. In particular, reduced

width

led to lower aerodynamic drag. Of course, the engine / chassis must be

made stiffer to cope with the additional stressed from rear axle.

Today,

F1 cars still use this basic structure.

Characteristics

of carbon-fiber

monocoque:

| Advantage: |

The

lightest

and stiffest chassis. |

| Disadvantage: |

By far the

most expensive. |

| Who use it ? |

McLaren F1,

Bugatti EB110SS,

Ferrari F50. |

Aluminium Space Frame

Audi ASF

Audi

A8 is the first mass production car featuring Aluminium Space Frame

chassis.

Developed in conjunction with US aluminium maker Alcoa, ASF is intended

to replace conventional steel monocoque mainly for the benefit of

lightness.

Audi claimed A8's ASF is 40% lighter yet 40% stiffer than contemporary

steel monocoque. This enable the 4WD-equipped A8 to be lighter than BMW

740i.

Audi

A8 is the first mass production car featuring Aluminium Space Frame

chassis.

Developed in conjunction with US aluminium maker Alcoa, ASF is intended

to replace conventional steel monocoque mainly for the benefit of

lightness.

Audi claimed A8's ASF is 40% lighter yet 40% stiffer than contemporary

steel monocoque. This enable the 4WD-equipped A8 to be lighter than BMW

740i.

ASF consists of

extruded

aluminum sections, vacuum die cast components and aluminum sheets of

different

thicknesses. They all are made of high-strength aluminium alloy. At the

highly stressed corners and joints, extruded sections are connected by

complex aluminum die casting (nodes). Besides, new fastening methods

were

developed to join the body parts together. It's quite complex and

production

cost is far higher than steel monocoque.

The Audi A2 employed

the

second generation of ASF technology, which involves larger but fewer

frames,

hence fewer nodes and requires fewer welding. Laser welding is also

extensively

used in the bonding. All these helped reducing the production cost to

the

extent that the cheap A2 can afford it.

| Advantage: |

Lighter

than

steel monocoque. As space efficient as it. |

| Disadvantage: |

Still

expensive for mass

production |

| Who use it ? |

Audi |

Lotus Elise

|

Elise's

revolutionary chassis

is made of extruded aluminium sections joined by glue and rivets. New

technology

can make the extruded parts curvy, as seen in the side members. This

allow

large part to be made in single piece, thus save bonding and weight. |

To Lotus and other

low-volume

sports car makers, Audi's ASF technology is actually infeasible because

it requires big pressing machines. But there is an alternative:

extruding.

Extrusion dies are very cheap, yet they can make extruded aluminium in

any thickness. The question is: how to bond the extruded parts together

to form a rigid chassis ?

Renault Sport Spider

bonds

them by spot welding, while Lotus Elise uses glue and rivet to do so.

Comparing

their specification and you will know how superior the Elise is:

|

|

Renault

Sport Spider

|

Lotus

Elise

|

|

Weight of

chassis

|

80 kg

|

65 kg

|

|

Torsional

stiffness

|

10,000

Nm/degree

|

11,000

Nm/degree

|

|

Thickness of

extrusion

|

3 mm

|

1.5 mm

|

Lotus's technology was

originated

by its supplier, Hydro Aluminium of Denmark. Hydro discovered that

aluminium

extrusion can be bonded by epoxy resin (glue) if it is adequately

prepared

by a special chemical in the bonding surface. Surprisingly, glue can

bond

the sections together strongly and reliably. Most important, the

aluminium

extruded sections can be made much thinner than traditional welding

technique.

Why ? because welded joints are weak, so the thickness of material

should

be increased throughout a member just to make a joint strong enough.

Therefore

Elise's chassis could be lighter yet stiffer.

|

Glue can be

clearly seen

during production. |

Unquestionably, Lotus

Elise's

aluminium chassis is a revolution. I expect to see more British

specialty

cars to go this way.

| Advantage: |

Cheap

for low-volume

production. Offers the highest rigidity-to-weight ratio besides carbon

fiber monocoque. |

| Disadvantage: |

Not very space

efficient;

High door sill. |

| Who use it ? |

Lotus Elise,

forthcoming

Lotus M250, Opel Speedster |

Copyright©

1998-2000 by Mark Wan

AutoZine

Technical School

Return

to AutoZine home page

To

many sports cars specialists, glass-fiber is a perfect material. It

is lighter than steel and aluminium, easy to be shaped and rust-proof.

Moreover, the most important is that it is cheap to be produced in

small

quantity - it needs only simple tooling and a pair of hands. There are

a few drawbacks, though: 1) Higher tolerence in dimensions leads to

bigger

assembly gaps can be seen. This is usually percieved as lower visual

quality

compare with steel monocoque. 2) Image problem. Many people don't like

"plastic cars".

To

many sports cars specialists, glass-fiber is a perfect material. It

is lighter than steel and aluminium, easy to be shaped and rust-proof.

Moreover, the most important is that it is cheap to be produced in

small

quantity - it needs only simple tooling and a pair of hands. There are

a few drawbacks, though: 1) Higher tolerence in dimensions leads to

bigger

assembly gaps can be seen. This is usually percieved as lower visual

quality

compare with steel monocoque. 2) Image problem. Many people don't like

"plastic cars".

Audi

A8 is the first mass production car featuring Aluminium Space Frame

chassis.

Developed in conjunction with US aluminium maker Alcoa, ASF is intended

to replace conventional steel monocoque mainly for the benefit of

lightness.

Audi claimed A8's ASF is 40% lighter yet 40% stiffer than contemporary

steel monocoque. This enable the 4WD-equipped A8 to be lighter than BMW

740i.

Audi

A8 is the first mass production car featuring Aluminium Space Frame

chassis.

Developed in conjunction with US aluminium maker Alcoa, ASF is intended

to replace conventional steel monocoque mainly for the benefit of

lightness.

Audi claimed A8's ASF is 40% lighter yet 40% stiffer than contemporary

steel monocoque. This enable the 4WD-equipped A8 to be lighter than BMW

740i.