|

AUTOZINE TECHNICAL SCHOOL

Multi-valve engines History

Multi-valve engines started life in 1912 on a Peugeot GP racing car. It was then briefly used by the pre-war Bentley and Bugatti. However, mass production on road cars came as late as 1970s - Ford Escort RS1600 (1970), Triumph Donomite Sprint (1973), Chevrolet Cosworth Vega (1975), Lotus Esprit (1976), Fiat 131 Abarth (1976) and BMW M1 (1979) were the earliest adopters.

By the mid-1980s, 4 valves per cylinder virtually became standard on high-performance cars, such as Ferrari 308 GTB Quattrovalvole (1982), BMW M635CSi (1983), Ferrari 288 GTO (1984), Mercedes 190E 2.3-16 (1984), Saab 9000 (1984, also the first to combine 4-valve and turbo on production car), BMW M5 (1985), Ferrari Testarossa (1985), Lamborghini Countach QV (1985) and Volkswagen Golf GTi 16V (1985), let alone those Group B rally specials. However, it was the Japanese who came first to put multi-valve technology on mass production cars that everybody can afford. Honda Civic adopted 3-valve engines as standard in 1983 and 4-valve engines in 1987. Toyota mass-marketed its high-performance 1.6-liter 16V engine on Corolla coupe / Truneo (1983) and MR2 (1984), then equipped the bread-and-butter Corolla with 4-valve engines in 1987. They standardized multi-valve engines nearly a decade earlier than Western car makers ! Advantages and Disadvantages Multi-valve engines have mainly 3 advantages. Firstly, it increases the coverage of valves over the combustion chamber, allowing faster breathing thus enhance power at high rev. Secondly, it allows the spark plug to be positioned in the center of combustion chamber, enabling quicker flame propagation, more even and more efficient burning. Thirdly, using more but smaller valves instead of two large valves means lower mass for each valve. This prevent the valves "float" from its designed position at very high rev, thus enabling the engine to rev higher and make more power as a result.

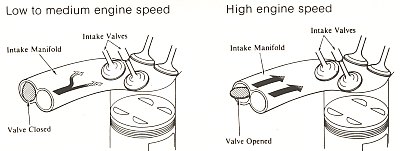

On the downside, multi-valve engines use more components, thus they carry more weight and higher costs. While these disadvantages can be largely overcome by mass production, another problem took some years to solve. The early multi-valve engines were not renowned for tractability. At low to medium rpm they actually produced less torque than the equivalent 2-valve engines. Why? Because the larger valve area resulted in slower air flow in the intake manifold. At low rpm, the very slow air flow led to imperfect mixing of fuel and air, resulting in knocking and reducing power. For a racing car or sports car, that might not be a big problem, but for regular passenger cars the lack of tractability is deemed to be unacceptable. Solutions Toyota T-VIS In response to the aforementioned drawback, Toyota introduced T-VIS (Toyota Variable Intake System) in the mid-1980s. T-VIS accelerated low-speed air flow in the intake manifold. The theory was quite simple: the intake manifold of each cylinder was split into two separate sub-manifolds which joint together near the intake valves. A butterfly valve was added at one of the sub-manifolds. At below 4,650 rpm the butterfly valve remained closed so to raise the velocity of air flow in the intake manifold. As fuel was injected at this section of manifold, better air-fuel mixing could be obtained. At high rev, the butterfly opened to allow maximum air flow.    The T-VIS was used on performance models like AE86, MR2 and Celica. However, for its mainstream passenger cars, Toyota dropped this feature and adopted a small-diameter intake manifold/port design for cost reasons. Many other car makers went the same way, sacrificing a bit top-end power for better low-speed tractability. Modern Approaches In recent years, the low-speed tractability problem can be dealt with a variety of solutions, such as variable intake manifold (which boosts low-end torque), variable valve timing (which may delay the opening of intake valves at low rev to accelerate air flow) and variable valve lift (which varies degree of lift hence air flow speed). However, the ultimate solution must be direct fuel injection. Fuel is now injected precisely into the combustion chamber rather than the intake manifold. Complete vaporization is realized by the high-pressure injector as well as swirl effect. Number of Valves 3-valve engines The earliest mass production multi-valve engines were 3-valves because of its simple construction - it needs only a single camshaft to drive both intake valves and the exhaust valve of each cylinder. Today, there are still some low-end cars using this cheap but less efficient design.

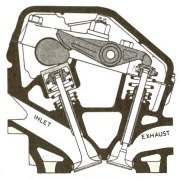

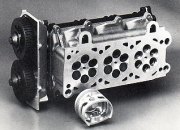

4-valve engines Today, by far the majority of multi-valve engines employ 4 valves per cylinder. Most 4-valve engines employ twin-cam (DOHC) for its obvious benefits, for instance, cross-flow intake/exhaust, low inertia and friction, and the allowance of independent intake and exhaust variable cam phasing. However, some cost-conscious engines (most by Honda and Mitsubishi) still employ single-cam (SOHC) to drive all valves. Like the aforementioned Triumph Donomite Sprint, these engines use rocker arms to transfer the motion from camshaft to exhaust valves. The resultant higher friction and inertia hampers revvability, but it does not matter for applications on family cars. 5-valve engines Yamaha was the expert of 5-valve technology. Since the mid-1980s it had been using 5-valve technology on its high-performance motorcycles. In 1991, it helped Toyota to produce a 1.6-liter 20-valve engine for Corolla Levin (Trueno). This was perhaps the earliest 5-valve application on road cars. Closely followed that were Bugatti EB110 and LCC Rocket (powered by Yamaha bike engine). Meanwhile, having used 5-valve technology successfully in F1 cars, Ferrari applied it to F355 and F50. However, the only manufacturer ever put it to mass production was Audi (which also benefited Volkswagen group). For about a decade, most engines produced by Audi were equipped with 5-valve heads.

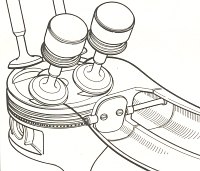

All 5-valve engines have 3 intake valves and 2 exhaust valves per cylinder, still arranged as cross-flow. The exhaust valves are larger, but in terms of total area intake valves is larger. The intake valves do not necessarily open at the same time. For example, on Ferrari F355, the outer intake valves opened 10° earlier than the middle valve. This created swirl, enabling better air/fuel mixing, hence more efficient burning and cleaner emission. In theory, 5 valves per cylinder may offer larger valve area than 4-valver for better breathing. The smaller and lighter intake valves also enable the engine to rev higher without worrying of "valve floating". The latter reason was especially crucial to high-revving superbike engines and racing motors. However, the overall advantage of 5-valve technology over 4-valver has always been arguable, because it involves more components hence more mass and friction. Cross-flow breathing is also less ideal than in the case of 4-valver. In 1993, Ferrari gave us a preliminary answer: its F1 motor returned to 4-valve heads. This was made possible as new pneumatic valve springs could solve the "valve floating" problem. In the road car department, Ferrari replaced the 5-valve 360 Modena with 4-valve F430 in 2005 and still capable of making more horsepower per liter. This broke the legend of 5-valve technology. By the mid-2000s, Audi started reverting to 4-valve engines as well, ending the short-lived fever of 5-valver. 6-valve or more ? Until now, anything more than 5 valves per cylinder is still a dream... a wild dream actually.

|

||||||||||||||

| Copyright© 1997-2011 by Mark Wan @ AutoZine |