|

AUTOZINE TECHNICAL SCHOOL

Cam-changing + Cam-phasing VVT Combining cam-changing VVT and cam-phasing

VVT may satisfy the requirement of both top-end power and flexibility

throughout the whole rev range, though it is inevitably more complex.

At the time of writing, only Toyota and Porsche have such designs.

However, I believe in the future more and more sports cars will adopt

this kind of VVT.

Example: Toyota VVTL-i  Toyota’s

VVTL-i is the most sophisticated VVT design yet. Its powerful functions

include: Toyota’s

VVTL-i is the most sophisticated VVT design yet. Its powerful functions

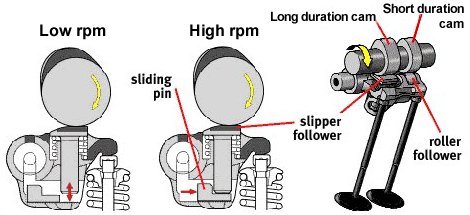

include: - Continuous cam-phasing variable valve timing - 2-stage variable valve lift plus valve-opening duration - Applied to both intake and exhaust valves The system could be seen as a combination of the existing VVT-i and Honda’s VTEC, although the mechanism for the variable lift is different from Honda. Like VVT-i, the variable valve timing is implemented by shifting the phase angle of the whole camshaft forward or reverse by means of a hydraulic actuator attached to the end of the camshaft. The timing is calculated by the engine management system with engine rev, acceleration, going up hill or down hill etc. taken into consideration. Moreover, the variation is continuous across a wide range of up to 60°, therefore the variable timing alone is perhaps the most perfect design up to now. What makes the VVTL-i superior to the ordinary VVT-i is the "L", which stands for Lift (valve lift) as everybody knows. Let’s see the following illustration:  Like VTEC, Toyota’s system uses a single rocker arm follower to actuate both intake valves. It also has 2 cam lobes acting on that rocker arm follower, the lobes have different profile - one with longer valve-opening duration profile (for high speed), another with shorter valve-opening duration profile (for low speed). At low speed, the slow cam actuates the rocker arm follower via a roller bearing (to reduce friction). The high-speed cam does not have any effect to the rocker follower because there is sufficient spacing underneath its hydraulic tappet.  < A flat

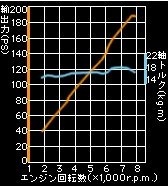

torque output (blue curve) < A flat

torque output (blue curve)When the engine revs passed the threshold point, the sliding pin is pushed by hydraulic pressure to fill the space. The high-speed cam becomes effective. Note that the fast cam provides a longer valve-opening duration while the sliding pin adds valve lift. (For Honda VTEC, both the duration and lift are implemented by the cam lobes) Obviously, the variable valve-opening duration is a 2-stage design, unlike Rover VVC’s continuous design. However, VVTL-i offers variable lift, which lifts its top end power output a lot. Compare with Honda VTEC and similar designs for Mitsubishi and Nissan, Toyota’s system has continuously variable cam phasing which helps it to achieve far better low to medium rev flexibility. Therefore it is easily the most versatile VVT as of the time of writing. However, it is also more complex and expensive to build.

Example 2: Porsche Variocam Plus

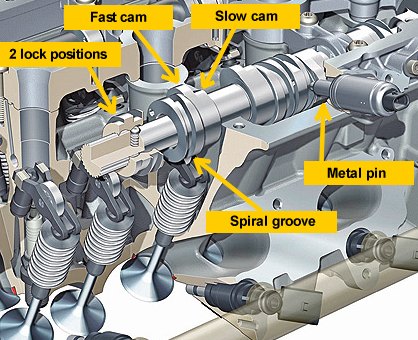

Porsche’s Variocam Plus was said to be developed from the Variocam which serves the Carrera and Boxster. However, I found their mechanisms virtually share nothing. The Variocam was first introduced to the 968 in 1991. It used timing chain to vary the phase angle of camshaft, thus provided 3-stage variable valve timing. 996 Carrera and 986 Boxster also used the same system. This design is unique and patented, but it is actually inferior to the hydraulic cam phasers favoured by other car makers, especially as it doesn’t allow as much variation to phase angle. Therefore, the Variocam Plus used in the new 996 Turbo finally follows the industrial trend to use hydraulic cam phasers instead of chain. However, the most influential changes of the "Plus" is the addition of variable valve lift. It is implemented by using variable hydraulic tappets. As shown in the picture, each valve is served by 3 cam lobes - the center one has obviously less lift (3 mm only) and shorter duration for valve opening. In other words, it is the "slow" cam. The outer two cam lobes are exactly the same, with fast timing and high lift (10 mm). Selection of cam lobes is made by the variable tappet, which actually consists of an inner tappet and an outer (ring-shape) tappet. They could by locked together by a hydraulic-operated pin passing through them. In this way, the "fast" cam lobes actuate the valve, providing high lift and long duration opening. If the tappets are not locked together, the valve will be actuated by the "slow" cam lobe via the inner tappet. The outer tappet will move independent of the valve lifter. As seen, the variable lift mechanism is unusually simple and space-saving. The variable tappets are just marginally heavier than ordinary tappets and engage nearly no more space.

Example 3: Honda i-VTEC - Continuous cam-phasing variable valve timing - 2-stage variable valve lift plus valve-opening duration - Can be applied to both intake and exhaust valves Basically, the camshaft is purely VTEC - with different cam lobes for implementing 2-stage variable lift and timing. On the other hand, the camshaft can be phase-shifted by a hydraulic actuator at the end of the camshaft, so valve timing can be varied continuously according to need. The i-VTEC was first introduced in Stream MPV, in which only the intake side applies i-VTEC. Theoretically, it can be applied to both intake and exhaust camshafts, but Honda seemed less generous than Toyota - even the Integra Type R uses only i-VTEC at intake side plus the regular VTEC at exhaust side.

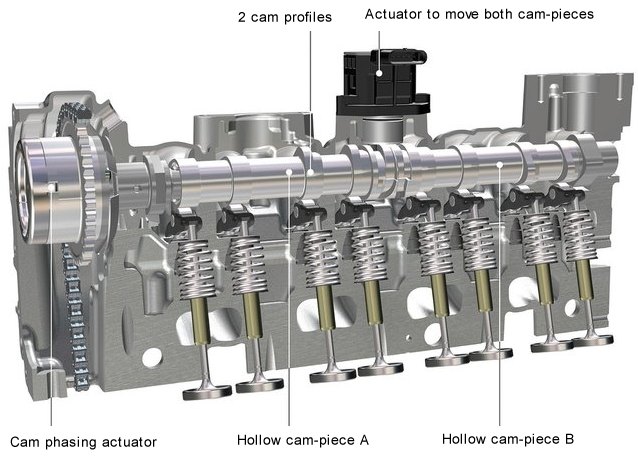

Example 4: Audi Valvelift Audi's Valvelift system made its debut in the company's 2.8-liter direct injection V6 and is expected to be expanded for use in many other members of the 90-degree V6 / V8 family. The Valvelift system itself is a cam-changing type VVT, but as Audi's V6 / V8 engines are already equipped with cam-phasing VVT, I classify it as the combination type VVT here. Compare with Honda's or Toyota's mechanism, Audi's seems to be simpler and more efficient. It does the variable lift without using complex intermediate parts (e.g. hydraulic-operated lockable rocker arms), so it saves space and weight while reduces frictional loss and, theoretically, improves revvability. How can Audi do that? the answer is: in Valvelift system, the cam pieces can slide in longitudinal direction to change the actuating cams.  Each intake valve can be actuated by a fast cam (11mm lift) or a slow cam (5.7mm in one intake valve and 2mm in another in order to create swirl in the air flow for better fuel mixing at low speed). The two cams are mounted on a single cam piece. Which cam acts on the roller cam follower depends on the longitudinal position of cam piece. This is controlled by a pair of metal pins incorporated at the cam cover. There is a spiral groove rolled into the camshaft. When one metal pin is lowered, it engages the spiral groove on the camshaft and pushes the cam piece by 7mm in longitudinal direction. A spring-loaded locker will lock the cam piece in the new position. In this way, the operating cams are changed from one set to another set. To revert to another cam, another metal pin presses against a reverse spiral groove and moves the cam piece back to the original position. The cam piece is locked by the spring-loaded locker again. The change from one cam set to another takes one combustion cycle, or two engine revolutions. As Audi reprogrammed the ignition and electronic throttle to smoothen the transition between the two cam sets, it can be hardly detectable. Theoretically, the Valvelift system should deliver better power than Toyota's VVTL-i and Honda's i-VTEC, but in the 2.8-liter V6 its priority is put on fuel economy. We shall see whether Audi will use its advantage in its performance engines in the future.

Example 5: Mercedes Camtronic Mercedes introduced its own variable valve lift system on the new M270 series four-cylinder engine in 2012. Called Camtronic, its main objective is not to enhance power but to reduce fuel consumption. At light or part-load, the Camtronic switches to low-lift cams to limit the amount of air intake, thus the throttle butterfly can remain wide open and reduce pumping loss. This principle is similar to BMW's Valvetronic system, but the Camtronic is a 2-stage system rather than continuously variable. Mercedes argues that it achieves 80 percent of the benefit of a continuous system while costing only a fraction, as it involves fewer parts. The Camtronic saves 4 percent of fuel in European combined cycle testing.  The mechanism of Camtronic is pretty simple. The intake camshaft is served with a conventional variable cam-phasing actuator at its end as well as the Camtronic variable valve lift components. The camshaft itself consists of an inner carrier shaft and 2 hollow cam-pieces, each serves 2 adjacent cylinders. Each cam has 2 profiles (low lift and high lift), which of them is engaged depends on the longitudinal position of the cam-pieces. When the engine needs to switch cam profiles, a centrally-mounted actuator applies steel pins to the grooves on the cam-pieces, thus the rotation of camshaft causes the cam-pieces to slide in longitudinal direction and engage the alternative cam profiles within one revolution. The principle of Camtronic is very similar to Audi's valvelift, but it uses fewer cam-pieces and actuator thus is less costly to build.

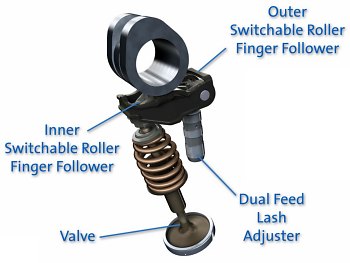

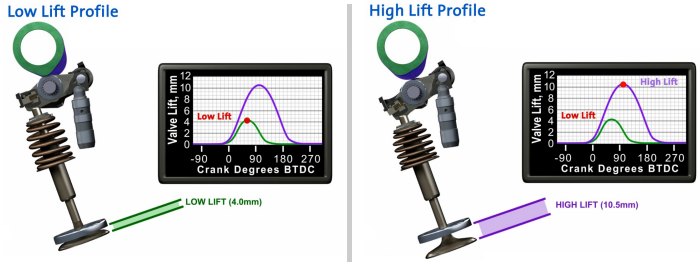

Example 6: GM iVLC General Motors introduced its first variable valve lift system on its direct injection 2.5-liter four-cylinder enigne in late 2012. Its first applications were Chevrolet Impala and Malibu. The iVLC (Intake Valve Lift Control) applies to the intake camshaft and is compatible with variable cam phasing. It utilizes a special roller finger follower to implement the variable lift function. This finger follower consists of 2 parts - an inner roller finger follower which acts on the intake valve directly, and an outer roller finger follower. They can be detached or locked together by a lash adjuster, which is driven by oil pressure and controlled by ECU.  As in most other VVL designs, each of its intake valve is served with 3 cam profiles, i.e. 2 identical high-lift / long-duration "fast cams" sandwiching a low-lift / short-duration "slow cam". They activate the intake valve via the roller finger follower. The outer fast cams press on the outer finger follower. At low rpm, the lash is unlocked, thus the outer finger follower moves up and down freely without actually pressing on the valve. Meanwhile, the inner slow cam acts on the inner roller finger follower and activates the valve, therefore the engine runs with low valve lift.  At high rpm, where

more air flow is demanded, the lash locks the outer and inner finger

followers together, thus the fast cams can activate the valve via the

locked finger followers.

Because of the 2-piece finger followers, I suppose iVLC could introduce more frictional loss than most other VVL systems, especially in low-lift mode. The additional moving mass could also limit its revvability a little. Judging from its output figures alone, the first 2.5-liter iVLC engine does not show any obvious advantages over the old engine.

|

||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||

| Copyright© 1997-2014 by Mark Wan @ AutoZine |