|

AUTOZINE TECHNICAL SCHOOL

Steering Steer-by-Wire -

Infiniti Q50 Direct Adaptive Steering (2013)

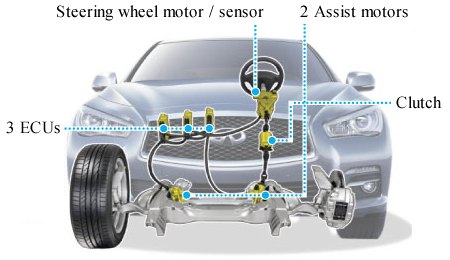

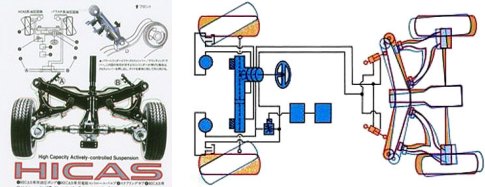

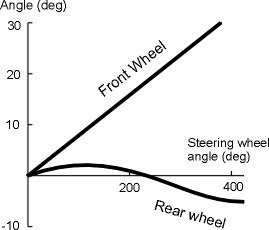

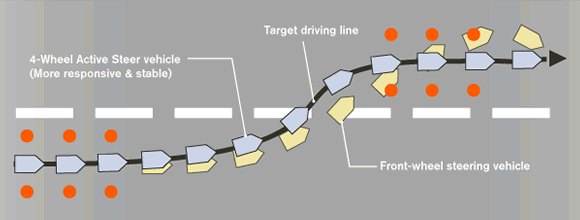

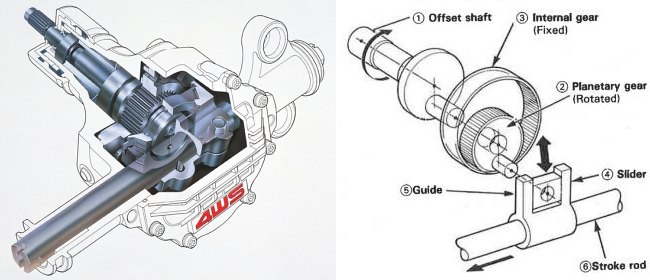

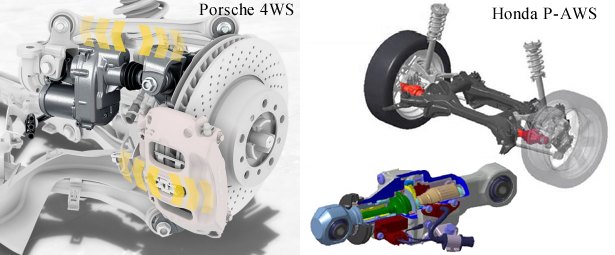

You might not notice, most of the driver controls of modern cars have been replaced with electronic ones or so-called "by-wire" controls, such as electronic throttle, electronic gearshift and brake-by-wire. This allows computer to intervene the controls to improve safety and driving precision. Moreover, it paves the way for the future semi or full autonomous driving. The last control to accept by-wire conversion is steering. There are 2 major hurdles steer-by-wire has to overcome: 1. The system shall be fault-proof to avoid accidents. Many legislations require a mechanical backup system to function in case of electronic or software failures. 2. Since the physical connection between steering wheel and front wheels no longer exists, the steer-by-wire system should be able to generate artificial feedback to the driver, otherwise the driving experience would be as unreal as playing video games. In 2013, Nissan's Infiniti Q50 became the first production car to employ steer-by-wire technology. Its DAS (Direct Adaptive Steering) system consists of the following parts:  How does it work? 1. The steering wheel sensor detects the steering angle and torque applied by the driver, then tells the ECU. 2. ECU takes also other parameters, such as speed and vehicle stability into account to determine the amount of steering needed. 3. Two assist motors at the steering rack actuate the steering according to the command of ECU. 4. ECU tells the steering wheel motor to generate resistance as a feedback to the driver. How to avoid system failure? 1. The ECU actually consists of 3 individual ECUs doing the same computation in parallel. Their results will be compared before sending out commands. In case one of them fails, its result will be different from the other two, thus the system will adopt the result of the other two. 2. What if 2 of them or all of them fail? The system will activate the clutch and revert to mechanical steering connection. Since the clutch opens only when energized, in case of electronics failure or engine shutdown the clutch will close automatically. What is the benefit of DAS? Firstly, it allows the steering to be fully variable, no matter ratio or assistance, and the adjustment range could be widened as it is no longer limited by mechanical design. Secondly, the complete separation of steering rack from the steering wheel means the latter is no longer troubled by steering kickback or vibration, so the car can mount the steering rack rigidly to the chassis without using rubber bushings. This minimizes slack thus speeds up steering response and improves precision. Thirdly, steer-by-wire allows more parameters to be taken into consideration. For example, ECU can adjust the steering angle to offset the influence of bump steer, road camber or side wind. Lastly but not least, although this function is not yet available to Infiniti Q50, it is compatible with autonomous driving technology. The computer may simply use it to drive or park the car by itself without the intervention of human. And the drawback? Feel, or the lack of it. The DAS uses a simple motor to generate resistance back to the driver's hand. Judging from its actual performance on Q50, it is obviously not up to the job to mimic the feedback of conventional steering. Without a direct connection to the rack, in principle it is impossible to deliver the tactile feedback of a good steering, because the motor cannot generate kickback and small vibration which are also vital to know what's going on at the front wheels. Another drawback is the additional costs, especially the need for 3 powerful ECUs. That is probably why other manufacturers are reluctant to introduce steer-by-wire. 4-Wheel Steering The full history of 4WS 4-Wheel Steering is not a new concept. Its history can be traced back to at least 1938, when Mercedes-Benz built a military offroader called 170VL. Its rear wheels could steer in opposite direction to shorten turning radius. However, Mercedes did not apply 4WS to its road cars. The first mass production application has to be the 1985 Nissan Skyline GTS (R31). Unlike the Mercedes, its HICAS system aimed at improving stability in high-speed cornering or lane changing rather than enhancing maneuverability. That's why it worked only above 30 kph, and it steered the rear wheels only in the same direction as the front. The rear steering angle varied purely according to speed, but was ultimately limited to merely 0.5 degree. Anyway, the first generation HICAS did not qualify for our definition of 4WS, because it simply used a pair of hydraulic cylinders to deflect the whole rear suspension subframe together with suspensions within the tolerance of rubber bushings (see picture below). That's why the steering angle is very limited.  The first generation Nissan HICAS on R31 Skyline (left) and Mid4 concept car (right). Therefore, the first production 4WS car should be the 1987 Honda Prelude coupe. The most special thing about it and also a patented innovation was the non-linear relationship between front and rear wheel angles. As shown in the graph below, when turning the steering wheel, initially the rear wheels steer slightly (at most 1.7 degree) in the same direction as the front wheels. This improves stability during high-speed turning or lane changing. Keep turning the steering wheel would reverse the direction of rear wheels (at most 5 degrees). This is used to quicken low-speed turning. It shortens the turning radius, making the Prelude like a much smaller car.    Surprisingly, the 4WS hardware on the 1987 Prelude was purely mechanical. It used a combination of eccentric shaft and planetary gears to implement the non-linear steering angle curve, pretty clever. On the downside, the relationship between front and rear wheel angles cannot be altered according to other factors. Another disadvantage is the need of an extra shaft to transfer the steering torque from the front to the rear axle. This robbed some space in the transmission tunnel and fuel tank, and the whole system added about 15 kg to the Prelude. Therefore, the next generation Prelude debuted in 1992 changed to an electronic mechanism.  The 4WS system of 1987 Honda Prelude Since the Skyline and Prelude, Japanese

manufacturers rushed to develop their own 4WS systems. By 1992, there

were already 2 dozen models featuring 4WS, including Nissan Skyline,

Laurel, Cefiro, Silvia, 300ZX, Infiniti Q45, Honda Prelude, Accord,

Mazda 626, 929, MX-6, RX-7, Mitsubishi Galant VR4, GTO/3000GT,

Diamante/Sigma, Toyota Celica and Soarer. Western car makers were left

behind in this game.

The most dedicated to 4WS tech was Nissan. By 1989, its original HICAS system was developed into Super HICAS in the Skyline R32 and 300ZX Z32. This time it became a true 4WS - an electronic-controlled hydraulic actuator steered the rear wheels through the toe-control links of rear suspensions, something made possible by switching from semi-trailing arm to multi-link suspensions on both cars. The range of adjustment increased to 1 degree. But the most unusual thing about Super HICAS was that, during the turn-in phase, it steered the rear wheels at opposite direction first in order to sharpen the turn-in, then revert to the same direction as the front wheels to stablise the car mid-corner. This greatly enhanced agility.  In the

next Skyline

R33, Super HICAS had its hydraulic actuator replaced with an

electrical one. Moreover, the upgraded control system considered not

only speed and steering wheel angle (as previously) but also yaw angle

of the car, so to make a better judgment to achieve the driver's

intended line. No wonder the R33 GT-R was so widely acclaimed. In the

next Skyline

R33, Super HICAS had its hydraulic actuator replaced with an

electrical one. Moreover, the upgraded control system considered not

only speed and steering wheel angle (as previously) but also yaw angle

of the car, so to make a better judgment to achieve the driver's

intended line. No wonder the R33 GT-R was so widely acclaimed. In R34 GT-R, the control strategy of Super HICAS got even cleverer. It referred to not only speed, angle and yaw but also the programmed models of cornering lines, which were the results of extensive testing in Nurburgring. Performance-wise, I think it is still the peak of 4WS as of today. Nevertheless, 1990s was unkind to Japan. The decade-long depression forced Japanese car makers to cut costs, thus 4WS was gradually abandoned. Meanwhile, the rise of electronic stability control and torque vectoring means 4WS was no longer the only solution. Entering the new millenium, it was once thought to be an outdated gimmick. Surprisingly, 4WS makes a comeback in the 2010s. Western car makers finally show interest, at least on their larger luxury cars (e.g. BMW 5 and 7-Series), which need the agility provided by 4WS. More recently, top-tier European sports cars, such as Porsche 911 and Ferrari F12tdf, also found the benefits of 4WS to handling. Cheaper cars like Renault Laguna GT, Megane IV and Talisman offer it as option, too.  The electrical actuators of Porsche 911 Turbo (left) and Honda Legend / Acura RLX (right) are compact I suppose this is very much because suppliers have managed to minimize the size, weight and cost of 4WS hardware. Modern electrical actuators are so small that they can be added to a multi-link suspension without much alteration, and they add only a few kilograms to the car. As a result, 4WS is set to on the rise again. |

||

| Copyright© 1997-2016 by Mark Wan @ AutoZine |