AC

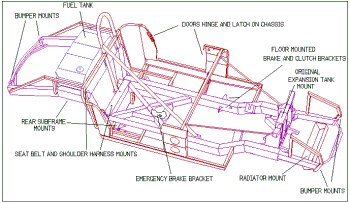

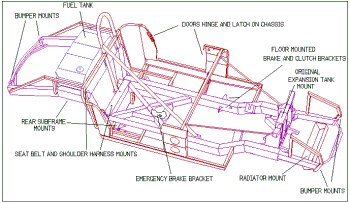

Cobra's chassis.

AC

Cobra's chassis.

AC

Cobra's chassis.

AC

Cobra's chassis.

| Advantage: | Well, it has no much advantage in these days ... it is easy and cheap for hand build, that's all. |

| Disadvantage: | Since it is a 2 dimensional structure, torsional rigidity is very much lower than other chassis, especially when dealing with vertical load or bumps. |

| Who use it ? | Most SUVs, classic cars, Lincoln Town Car, Ford Crown Victoria etc. |

|

|

Since the mid 60s,

many high-end

sports cars also adopted tubular space frame to enhance the rigidity /

weight ratio. However, many of them actually used space frames for the

front and rear structure and made the cabin out of monocoque to cut

cost.

| Advantage: | Very strong in any direction. (compare with ladder chassis and monocoque chassis of the same weight) |

| Disadvantage: | Very complex, costly and time consuming to be built. Impossible for robotised production. Besides, it engages a lot of space, raise the door sill and result in difficult access to the cabin. |

| Who use it ? | All Ferrari before the 360M, Lamborghini Diablo, Jaguar XJ220, Caterham, TVR etc. |

Today,

99% cars produced in this planet are made of steel monocoque chassis,

thanks to its low production cost and suitability to robotised

production.

Today,

99% cars produced in this planet are made of steel monocoque chassis,

thanks to its low production cost and suitability to robotised

production.

Monocoque is a one-piece structure which defines the overall shape of the car. While ladder, tubular space frame and backbone chassis provides only the stress members and need to build the body around them, monocoque chassis is already incoporated with the body in a single piece, as you can see in the above picture showing a Volvo V70.

In fact, the "one-piece" chassis is actually made by welding several pieces together. The floorpan, which is the largest piece, and other pieces are press-made by big stamping machines. They are spot welded together by robot arms (some even use laser welding) in a stream production line. The whole process just takes minutes. After that, some accessories like doors, bonnet, boot lid, side panels and roof are added.

Monocoque chassis also benefit crash protection. Because it uses a lot of metal, crumple zone can be built into the structure.

Another advantage is space efficiency. The whole structure is actually an outer shell, unlike other kinds of chassis, therefore there is no large transmission tunnel, high door sills, large roll over bar etc. Obviously, this is very attractive to mass production cars.

There are many disadvantages as well. It's very heavy, thanks to the amount of metal used. As the shell is shaped to benefit space efficiency rather than strength, and the pressed sheet metal is not as strong as metal tubes or extruded metal, the rigidity-to-weight ratio is also the lowest among all kinds of chassis bar the ancient ladder chassis. Moreover, as the whole monocoque is made of steel, unlike some other chassis which combine steel chassis and a body made of aluminium or glass-fiber, monocoque is hopelessly heavier than others.

Although monocoque is

suitable

for mass production by robots, it is nearly impossible for small-scale

production. The setup cost for the tooling is too expensive - big

stamping

machines and expensive mouldings. I believe Porsche is the only sports

car specialist has the production volume to afford that.

| Advantage: | Cheap for mass production. Inherently good crash protection. Space efficient. |

| Disadvantage: | Heavy. Impossible for small-volume production. |

| Who use it ? | Nearly all mass production cars, all current Porsche. |

Enter

the 90s, as tougher safety regulations ask for more rigid

chassis,

traditional steel monocoque becomes heavier than ever. As a result, car

makers turned to alternative materials to replace steel, most notable

is

aluminium. Although there is still no mass production car other than

Audi

A8 and A2 to completely eliminate steel in chassis construction, more

and

more cars use aluminium in body panels like bonnet and boot lid,

suspension

arms and mounting sub-frames. Unquestionably, this is not what the

steel

industry willing to see.

Enter

the 90s, as tougher safety regulations ask for more rigid

chassis,

traditional steel monocoque becomes heavier than ever. As a result, car

makers turned to alternative materials to replace steel, most notable

is

aluminium. Although there is still no mass production car other than

Audi

A8 and A2 to completely eliminate steel in chassis construction, more

and

more cars use aluminium in body panels like bonnet and boot lid,

suspension

arms and mounting sub-frames. Unquestionably, this is not what the

steel

industry willing to see.

Therefore, American's steel manufacturers hired Porsche Engineering Services to develop a new kind of steel monocoque technology calls Ultra Light Steel Auto Body (ULSAB). As shown in the picture, basically it has the same structure as a conventional monocoque. What it differs from its donor is in minor details - the use of "Hydroform" parts, sandwich steel and laser beam welding.

Hydroform is a new technique for shaping metal to desired shape, alternative to pressing. Conventional pressing use a heavy-weight machine to press a sheet metal into a die, this inevitably creates inhomogenous thickness - the edges and corners are always thinner than surfaces. To maintain a minimum thickness there for the benefit of stiffness, car designers have to choose thicker sheet metal than originally needed. Hydroform technique is very different. Instead of using sheet metal, it forms thin steel tubes. The steel tube is placed in a die which defines the desired shape, then fluid of very high pressure will be pumped into the tube and then expands the latter to the inner surface of the die. Since the pressure of fluid is uniformal, thickness of the steel made is also uniformal. As a result, designers can use the minimum thickness steel to reduce weight.

Sandwich steel is made from a thermoplastic (polypropylene) core in between two very thin steel skins. This combination is up to 50 percent lighter compared with a piece of homogenous steel without a penalty in performance. Because it shows excellent rigidity, it is applied in areas that call for high bending stiffness. However, it cannot be used in everywhere because it needs adhesive bonding or riveting instead of welding.

Compare with

conventional

monocoque, Porsche Engineering claimed it is 36% lighter yet over 50%

stiffer.

Although ULSAB was just annouced in early 1998, the new Opel Astra and

BMW 3-Series have already used it in some parts. I believe it will

eventually

replace conventional monocoque.

| Advantage: | Stronger and lighter then conventional monocoque without increasing production cost. |

| Disadvantage: | Still not strong or light enough for the best sports cars. |

| Who use it ? | Opel Astra, BMW 3-series |

Kia's

version Lotus Elan Mk II

Kia's

version Lotus Elan Mk II

Colin Chapman, the founder of Lotus, invented backbone chassis in his original Elan roadster. After failed in his experiment of glass-fibre monocoque, Chapman discovered a strong yet cheap chassis which had been existing for millions of years - backbone.

Backbone chassis is very simple: a strong tubular backbone (usually in rectangular section) connects the front and rear axle and provides nearly all the mechnical strength. Inside which there is space for the drive shaft in case of front-engine, rear-wheel drive layout like the Elan. The whole drivetrain, engine and suspensions are connected to both ends of the backbone. The body is built on the backbone, usually made of glass-fibre.

It's strong enough for smaller sports cars but not up to the job for high-end ones. In fact, the original De Tomaso Mangusta employed chassis supplied by Lotus and experienced chassis flex.

TVR's chassis is

adapted

from this design - instead of a rigid backbone, it uses a lattice

backbone

made of tubular space frames. That's lighter and stronger (mainly

because

the transmission tunnel is wider and higher).

| Advantage: | Stong enough for smaller sports cars. Easy to be made by hand thus cheap for low-volume production. Simple structure benefit cost. The most space-saving other than monocoque chassis. |

| Disadvantage: | Not strong enough for high-end sports cars. The backbone does not provide protection against side impact or off-set crash. Therefore it need other compensation means in the body. Cost ineffective for mass production. |

| Who use it ? | Lotus Esprit, Elan Mk II, TVR, Marcos. |