|

AUTOZINE TECHNICAL SCHOOL

Turbocharging Twin-turbo

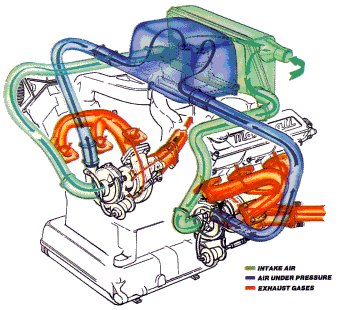

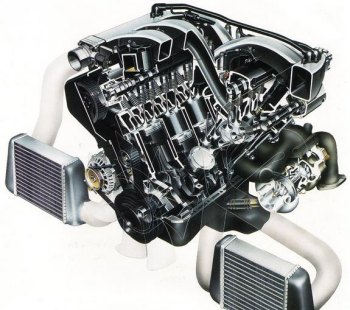

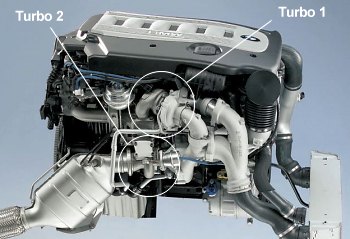

The use of twin-turbocharger is a question of both efficiency and packaging. A small engine is of course better to use a single turbo, because it does not produce sufficient exhaust gas to drive 2 turbos efficiently. For larger engines, it is better to use a pair of small turbochargers instead of a big one, because small turbines result in less turbo lag. But how large an engine needs to go twin-turbo? It depends. When I wrote this article for the first time in 1998, Subaru used twin-turbo on its 2.0-liter boxer engine. Many other car makers like Mitsubishi and Nissan used twin-turbo on engines displacing 2.5-liters or above. As the technology of turbochargers progressed, today's turbochargers achieve much lower inertia and turbo lag than the past. Consequently, the threshold between single and twin-turbo is also lifted. BMW, for example, changed its mainstream 3.0-liter straight-six from twin-turbo to single-turbo in 2009. Apart from a slight compromise in top-end power, it showed no deterioration in response and refinement. However, for performance versions like 1-Series M, BMW still keeps using twin-turbo to deliver the necessary horsepower. Packaging also governs the use of twin-turbo. For V-shape and boxer engines, it could be a headache to connect all cylinders to a single turbocharger. Twin-turbo can easily avoid the problem. As one turbo needs to serve only one cylinder bank, it can be put in close proxmity to the bank. As a result, the turbo piping can be greatly shortened, saving a lot of space in the engine compartment. Moreover, the shorter pipes lead to less turbo lag. Therefore, almost all turbocharged V-shape and boxer engines on the market employ twin-turbo. Generally speaking, there are 3 types of twin-turbo arrangement: Parallel, Sequential and 2-Stage Variable. Let's see how they work: Parallel Twin-turbo The simplest twin-turbo arrangement is Parallel Twin-turbo. Both turbos work independently at the same time. Most twin-turbos on the market are this type.

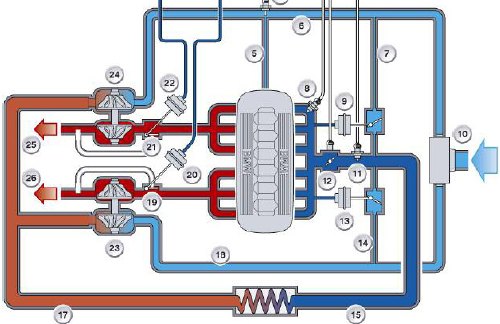

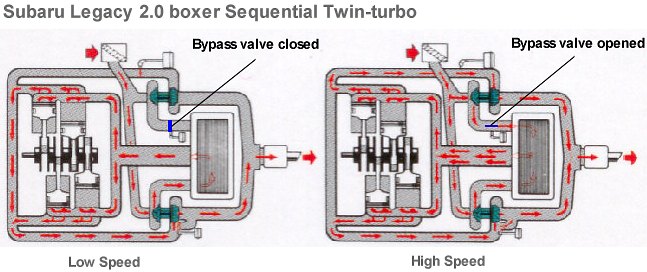

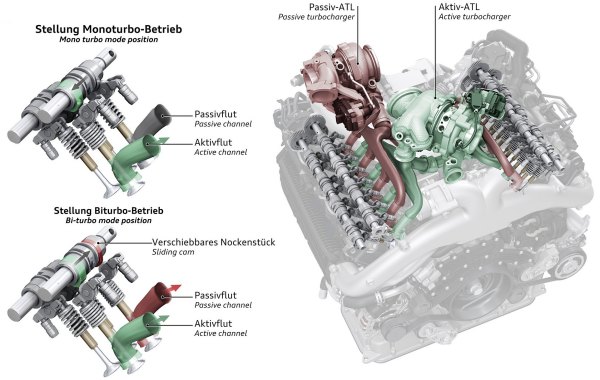

Sequential Twin-turbo To reduce turbo lag, some manufacturers opt for sequential twin-turbo. At low engine speed, all the limited amount of exhaust gas is directed to drive one of the turbos, leaving another idle. Therefore the first turbo can spool up more quickly. When the exhaust flow reaches sufficient amount to drive both turbos, the second turbo intervenes and helps reaching the maximum boost pressure. The switchover is implemented by a bypass valve, which is controlled by engine management system. Cars employing sequential twin-turbo include Porsche 959, Mazda RX-7 Mk3, Toyota Supra (last gen) and the 1990s Subaru Legacy.  Unfortunately, sequential twin-turbo requires very complicated connection of pipes, as both turbos have to be connected to all cylinders. This not only engages more space, but the longer pipes may offset some of the reduction in turbo lag. As modern technology has largely reduced turbo lag, sequential twin-turbo is no longer deemed to be necessary. Today, it has disappeared from production. Audi's VVL-driven sequential twin-turbo In 2016, a very special kind of sequential twin-turbo system made appearance on the 4-liter diesel V8 of Audi SQ7. It uses Audi's Valvelift variable valve lift system to select either one or two turbos. In each cylinder, the 2 exhaust valves are hermetrically separated, each leads to its own turbocharger (both turbos are the same size). One of the exhaust valves is equipped with the Valvelift mechanism. At low to medium rpm, the Valvelift switches to a zero-lift cam lobe so to shut down that exhaust valve. In this way, all the exhaust gas goes through another exhaust valve to drive one turbo. At higher rpms where more exhaust gas is produced, the Valvelift switches to a normal cam lobe and reactivates that exhaust valve. Now another turbo joins the work to provide full boost.  The biggest benefit of this design is that it saves the complicated interconnection between the two turbos, thus making the engine smaller. On the negative side, the cylinder runs only 1 exhaust valve at low to medium rev, limiting breathing. However, since Audi uses it on diesel engine, whose breathing rate is much slower than that of petrol engine, it does not compromise output. I guess the technology will not be used on petrol engines. 2-Stage Variable Twin-turbo In recently years, turbo lag has been largely resolved on gasoline engines, thanks to technology like close-coupled turbochargers (some are even integrated with exhaust manifolds) and low inertia small turbines. However, the same cannot be said to diesel engines. Diesel engines may produce power comparable to their petrol counterparts, but that need higher boost pressure hence larger turbochargers. It goes without saying that large turbos result in more turbo lag. Moreover, diesel engines tend to work at much lower rpm than petrol engines. This means in normal usage they produce less exhaust gas to feed the turbos. As a result, the turbo lag problem is made even worse. To deal with this problem, engineers developed a more sophisticated kind of twin-turbo specially for diesel engines. It is 2-stage variable twin-turbo.

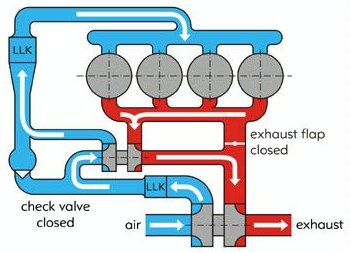

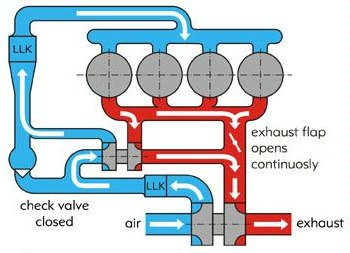

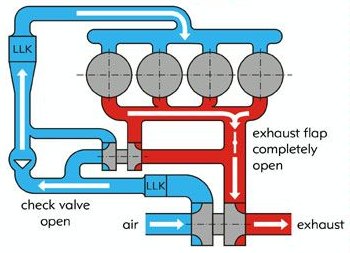

Unlike other twin-turbo systems, 2-stage variable twin-turbo employs different size turbos - a small one for quicker spool up at low rpm and a large turbo to take care of higher rev. They are connected in series so that the boost pressure from one turbo is further multiplied by another turbo, hence the name "2-stage". The distribution of exhaust gas is continuously variable, so the transition from small turbo to big turbo can be made seamless. Below is an example taken from an Opel system. Let's see how it works:

|

||||||||||||||||

|

||||||||||||||||

| Copyright© 1997-2011 by Mark Wan @ AutoZine |